OptiHULL outlines by its title what the project was about: optimal respectively optimized hull forms. That is, however, only half the truth. The R & D project had a broader scope: It focused on ship stern structures and on the definition of measures for the assessment of aftbody forms.

Yet, what is a “good” aftbody, respectively, a “bad”? How can one positively distinguish the two? Or, is there a gray area, and if so, how can it be assessed? Generally speaking, how can one investigate an aftbody?

FRIENDSHIP SYSTEMS worked in this joint research project together with initiator shipyard TKMS Blohm + Voss Nordseewerke and GL’s maritime consultancy provider FutureShip. FRIENDSHIP SYSTEMS contributed its engineering expertise and its expert skills in using its design optimization software CAESES.

What were the project’s tasks? What were the aim and interest of OptiHULL in the timeframe of May 2008 until June 2009?

R & D projects like OptiHULL often touch on two aspects and root in either one, sometimes both:

- One driver can be found in an academic interest. Literature and documentation lack the description of a complex topic, which has arisen time and again, but has not yet been profoundly examined.

- The other stems from an engineering desire or need, a motivation to find answers to urging tasks.

For OptiHULL, both and especially the latter aspect can be thought of as driving force. It was found by the initiator of the project, German shipyard Nordseewerke that regular potential flow calculations commonly used for optimization merely suit forebody investigations. They are less significant for aftbody structures. OptiHULL was thus set up to find methods and criteria for the assessment of aftbody structures. This was addressed in three major steps:

- Parametric description of aftbody structures

- Definition of criteria for the assessment of aftbody structures

- Development of inexpensive numerical analysis methods that can be conveniently used in formal optimizations

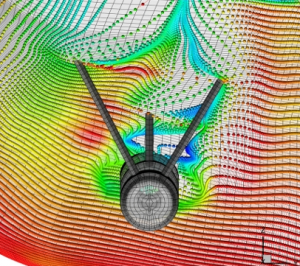

Globally, OptiHULL examined which criteria could be proven valid for the evaluation of aftbody forms so as to decide for “good” or “bad” aftbodies. How good is good? Consolidated objective measures for wake field assessment do not exist. Hence, wake fields are often approached with subjective measures that greatly rely on personal experience.

OptiHULL also checked proven methods, e.g. potential flow calculation, and extended them to the specific characteristics of aftbody forms. The approach asked if at all and to what extent existing methods can provide measures for the investigation of aftbody forms.

Research and development of the project were undertaken by all three collaborating parties with a focus on specific core tasks where considered useful. Nordseewerke included in the project the expertise both of FutureShip, which contributed FS-Flow, and of FRIENDSHIP SYSTEMS, which provided CAESES. The software has been used by TKMS Blohm + Voss Nordseewerke intensively before the project’s inauguration.

FRIENDSHIP SYSTEMS and Nordseewerke have previously collaborated in the OptiSWATH project, which focused on Small Waterplane Area Twin Hull (SWATH) forms, as well as on the optimization of a 3,400 TEU container vessel series. OptiHULL can be thought of as the continuation of this work experience.

What are the results of the project?

OptiHULL drove further the investigation of aftbody forms and applicable measures. It defined quality criteria and discussed the applicability of existing measures onto the specifics of aftbody structures. The project parties have exchanged results, which are now introduced into their specific work.