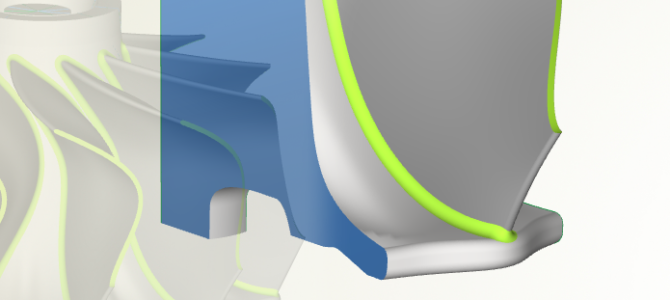

There is a new brief case study “Turbine Blade Optimization including Scallops for a Turbocharger” as an output from our recent efforts in the GAMMA research project. It describes the robust and variable geometry design of a turbine wheel. The purpose of this specific CAESES® model is to be able to conduct fully-automated shape optimizations with CFD and stress analysis at the same time.

Turbine wheel model for automated shape optimizations incl. variable scallops